SPECIFICALLY DESIGNED FOR OPEN TRENCH PIPELINE INSTALLATIONS

pau wrap® OT

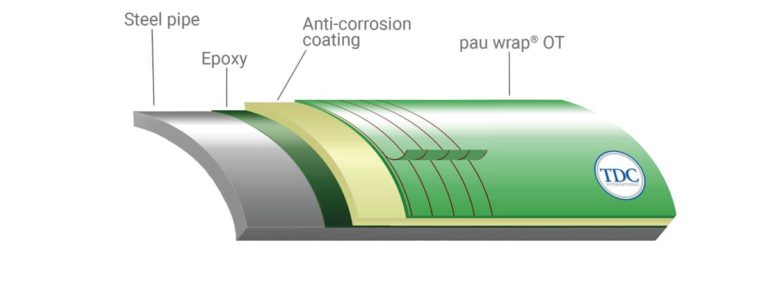

TDC’s pau wrap® OT was specially developed as a pipe protection solution against backfill materials for open trench installations. The factory-applied fibre reinforced composite has been engineered to withstand soil used for burying pipelines in rugged terrain, making it an ideal choice for projects that have particularly difficult geology, drainage issues, and steep right-of-way.

pau wrap® OT is a lightweight pipe protection product that mitigates the risk of damages during transportation, storage, the construction process and thereafter throughout the entire operating life of the pipeline. It provides protection against high impact loads, indentations, rock falls, gouging, and other abrasive conditions. As such, it eliminates the need for protective measures such as soil replacement or pipe protection mats, keeping the native soil and hydrology closer to their natural environmental state and minimising the foreign backfill substances used around the pipeline.

One of the key benefits of pau wrap® OT is its customisable design and flexibility, fully compatible with on-site cold bending, which is customarily used during the open trench pipeline construction process. This feature is a proprietary design characteristic specially made for open trench pau wrap® OT products. Depending on the pipeline project’s design and specifications, our engineering team works closely with the client to determine the final exact composition needed to meet the project’s individual requirements.

- For open trench installations in any geology

- Factory-applied directly on line pipe

- Customisable fibre-based composite

- Compatible with on-site bending

- Superior mechanical protection

- Lightweight

- Reducing construction complexity

- Removes the need for soil replacement or field-applied pipe protection measures

- Easy to transport and store

Features

- Extreme toughness

- Compatibility with cold bending at site

- High resistance to sharp-edged or abrasive backfill material

- High compressive strength

- No hinderance or interference to cathodic protection systems

- Manpower and machine deployment savings on site

- Can be applied to a variety of base layer coatings:

- Polyethylene (PE)

- Polypropylene (PP)

- Fusion bonded epoxy (FBE)

- Polyurethane (PU)

- Can be applied on any pipe size ranging from DN 80 to DN 1600 (others upon request)

Certificates & Standards

Our qualified and trained applicators inspect the pipes in accordance with our strict Quality Management System. pau wrap® OT is regularly audited and certified by:

- TÜV Octagon

- ISO 9001

- Client technical specifications and customer audits