SPECIAL NON-CIRCULAR PIPES MADE ENTIRELY FROM GRP MATERIALS FOR THE REHABILITATION AND NEW CONSTRUCTION OF SEWAGE / WASTEWATER PIPES

pau line®

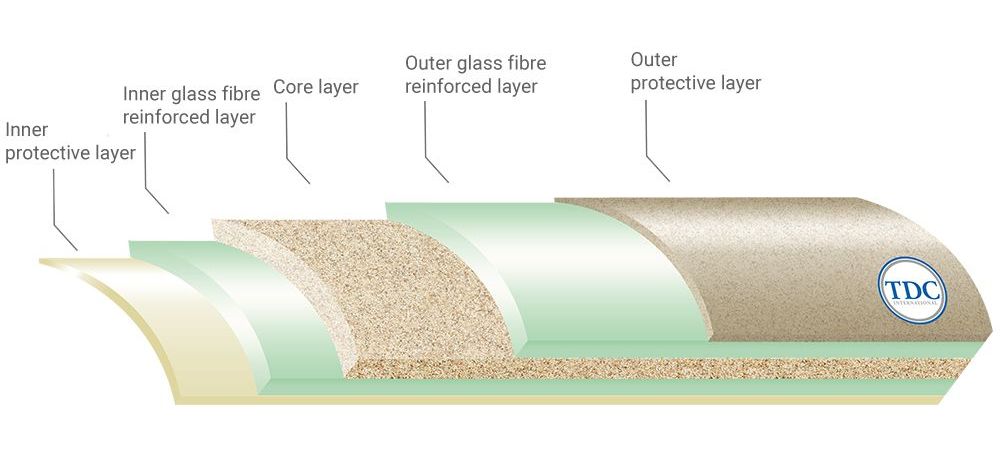

pau line® is TDC International’s low-weight sewage and wastewater solution made from high-quality glass fibre composites (GRP). Regardless of whether the non-circular pipes are inserted into an existing outdated drainage pipeline for rehabilitation or laid in an open trench for new construction, our pau line® product suite offers reliable quality standards with high static load capacity and other features such as chemical resistance to ensure a long service-life of the infrastructure. These complete GRP pipes are rated for wastewater operations, fulfilling the relevant ISO standards and regulations.

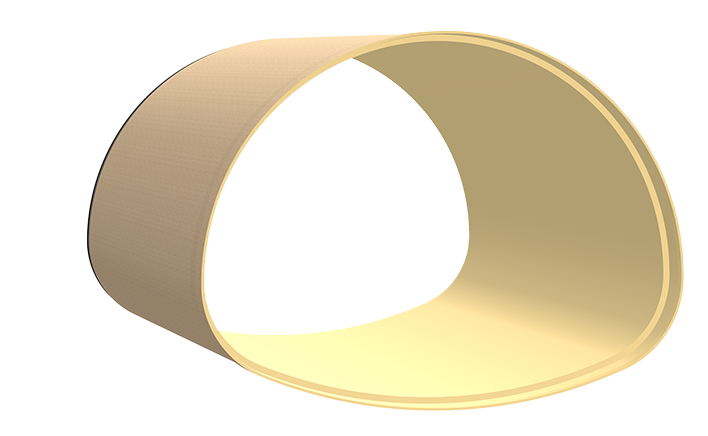

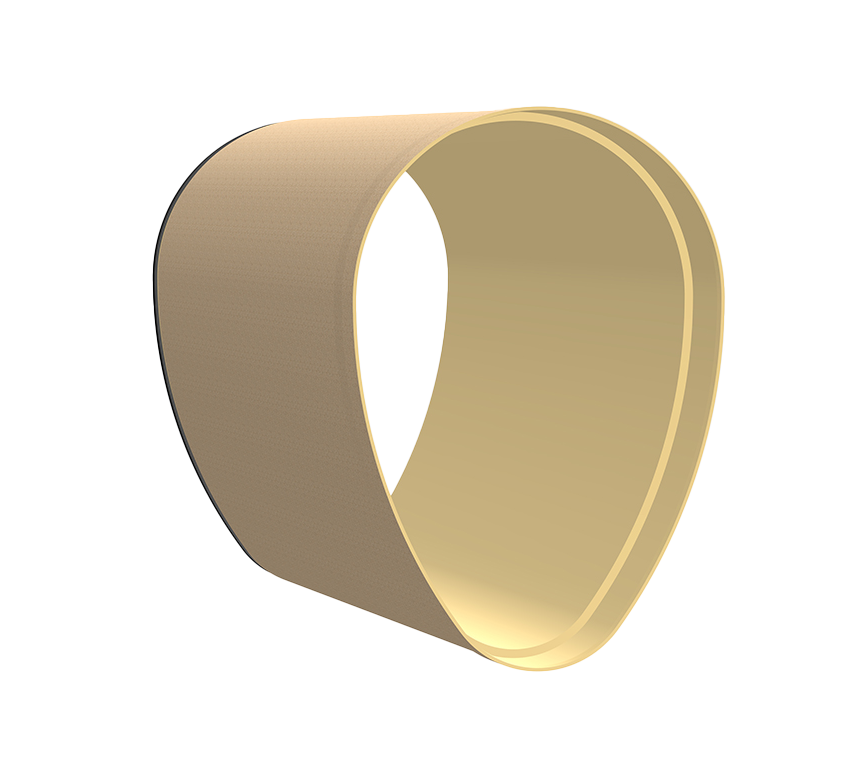

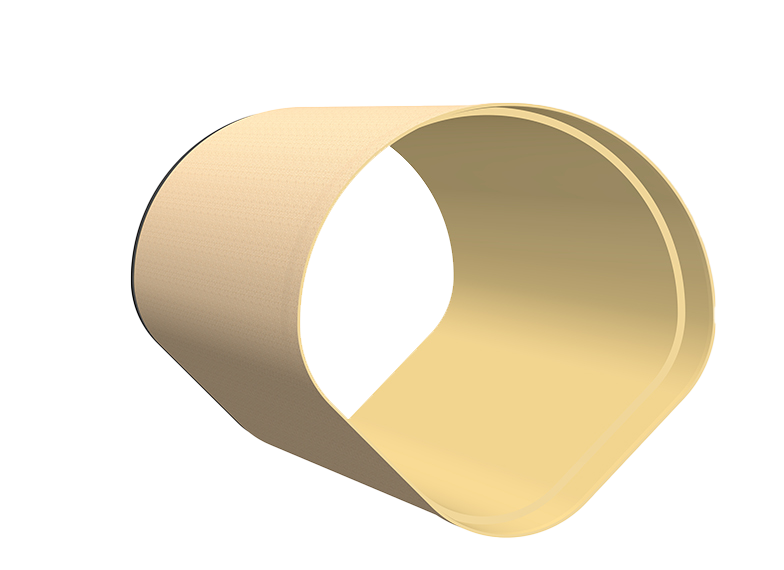

pau line® pipes are all custom made in-house at TDC’s factory in northeast Germany, according to the engineering, design, and technical requirements of the project. As these are custom-made, the pau line® products can be manufactured through our specialist non-circular production line into a variety of dimensions and unusual shapes, which are not round in profile (e.g. egg-shaped, arch, mouth, and dragon). This is especially important for rehabilitation of old sewage and wastewater pipelines, where the shape must match the shape of the obsolete tunnels that can no longer be used for drainage. After the rehabilitation process, these new pipelines are essentially commissioned as new lines and put into operations for many more years. In addition to these bespoke pipeline profiles, we can provide specific manhole solutions and fabricated parts for a seamlessly integrated system.

Our team has extensive experience and expertise in this market segment, which can be leveraged to assist our clients with the technical and practical challenges they face. Each project is different due to the specific requirements and relevant parameters and we are able to provide support at every stage of the project, including brainstorming on the design, product input, and installation.

Special profiles - examples

Features

- High static load capacity and strength

- Resilient to abrasion

- Non-reactive to various substances

- Long service life

- Reliable and high-quality products

- Very strong experience in production, design, and project execution

- Certification, testing, and compliance

Certificates & Standards

- Requirements according to ISO 16611:2020

- High pressure flush resistance tested according to DIN 19523

- Abrasion test according to DIN EN 295-3

- Chemical resistance according to DIN EN ISO 175

- Quality management system ISO 9001:2015