HIGHLY ABRASION RESISTANT INTEGRATED SPACERS

pau wrap® Spacers

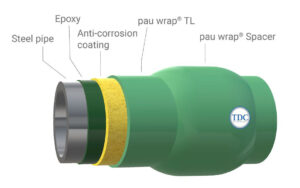

TDC’s pau wrap® Spacers are designed as an efficient sacrificial composite collar to protect pipelines that are inserted into microtunnels and casing pipes. These highly abrasion-resistant integrated spacers are designed in a unique way, to distribute the weight of the pipes as they travel through the tunnels and can be integrated seamlessly into our pau wrap® TL products or used on a standalone basis. During the installation, they enable the pipeline to stay at a minimum distance from the casing or tunnel internal surface and take on the full abrasion against the stresses caused by the pull forces and friction.

The exact design parameters for a pau wrap® Spacer are determined jointly between our technical team and the clients’ engineering team. The pau wrap® Spacers’ shape, thickness and wear properties can all be tailor-made to accommodate a project’s requirements and technical constraints, ensuring a perfect fit and optimal performance.

- Made of customisable composite

- For microtunnels and casing pipes

- Factory-applied directly on line pipe

- Additional mechanical protection as sacrificial layer for abrasion during installation

- Reducing construction complexity

- Removes the need for site-applied pipe protection measures

- Designed to customer requirements and project specifications

Features

- Highly abrasion resistant

- Works with various types of tunnel material

- High shear strength, no risk of displacement of spacers during pull-in operations

- Highly abrasion resistant

- High compressive strength

- Manpower savings on-site

- No risk of displacement of spacers during pulling operations

- No hinderance or interference to cathodic protection systems

- Can be applied on any pipe size ranging from DN 80 to DN 1600 (others upon request)

Certificates & Standards

Our qualified and trained applicators inspect the pipes in accordance with our strict Quality Management System. pau wrap® Spacers are regularly audited and certified by:

- TÜV Octagon

- ISO 9001

- Client technical specifications and customer audits