SPECIFICALLY DESIGNED FOR TRENCHLESS PIPELINE INSTALLATIONS

pau wrap® TL

“No-Dig” trenchless technologies refer to the complex technical construction methods used to install or rehabilitate underground pipelines. Their aim is to reduce the impact on natural environmental landscapes and ecosystems by minimising the need for excavation or other more disruptive practices. They also facilitate the successful installations of pipelines in places where open trenches could not be constructed, such as under roads, highways, rivers or other natural or man-made structures. One of the inherent challenges of these technologies, however, is the uncertainty surrounding the site’s geology. Strenuous, non-homogeneous, or complex geological formations can pose significant challenges to a trenchless project and cause substantial damages to the pipeline’s anti-corrosion coating, resulting in either unsuccessful drilling and thus failure of the project or extensive repairs incurring cost overruns and massive delays.

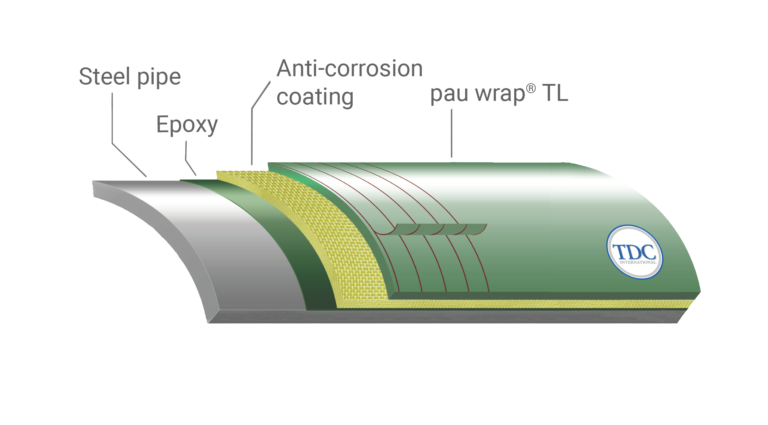

Over the years TDC has developed a unique product, pau wrap® TL, to protect pipelines from mechanical and corrosion damages during trenchless installation projects. Our unique lightweight, customisable fibre-based composite cladding can withstand harsh subterranean conditions like granite, gravel, and quartzite as examples, and offer durable protection against abrasion, corrosion, temperature, physical force, and chemicals. They have been successfully used across all typical “No-Dig” technologies including horizontal directional drilling, Direct Pipe®, and microtunnelling, etc.

pau wrap® TL products are produced directly over the outer surface of steel line pipes and their anti-corrosion coating in our factory in Germany to ensure consistent quality and uniformity. Our in-factory application process ensures sustainable approaches and the highest level of quality control and product reliability.

Features

- Extreme stability and resilience

- High shear strength on the anti-corrosion coating over the entire pipe length

- High compressive strength

- Highly abrasion resistant

- High elongation at break

- High resistance to mechanical stresses from the transportation and pipe installation process

- No hinderance or interference to cathodic protection systems

- Can be applied to a variety of base layer coatings:

- Polyethylene (PE)

- Polypropylene (PP)

- Fusion bonded epoxy (FBE)

- Polyurethane (PU)

- Can be applied on any pipe size ranging from DN 80 to DN 1600 (others upon request)

Certificates & Standards

Our qualified and trained applicators inspect the pipes in accordance with our strict Quality Management System. pau wrap® TL is regularly audited and certified by:

- TÜV Octagon

- ISO 9001

- Client technical specifications and customer audits